- Iyo kambani Beijing Jinyehong Metallurgical Machanical Equipment Corp.

- bjmmec@yeah.net

- +86 15201347740/+86 13121182715

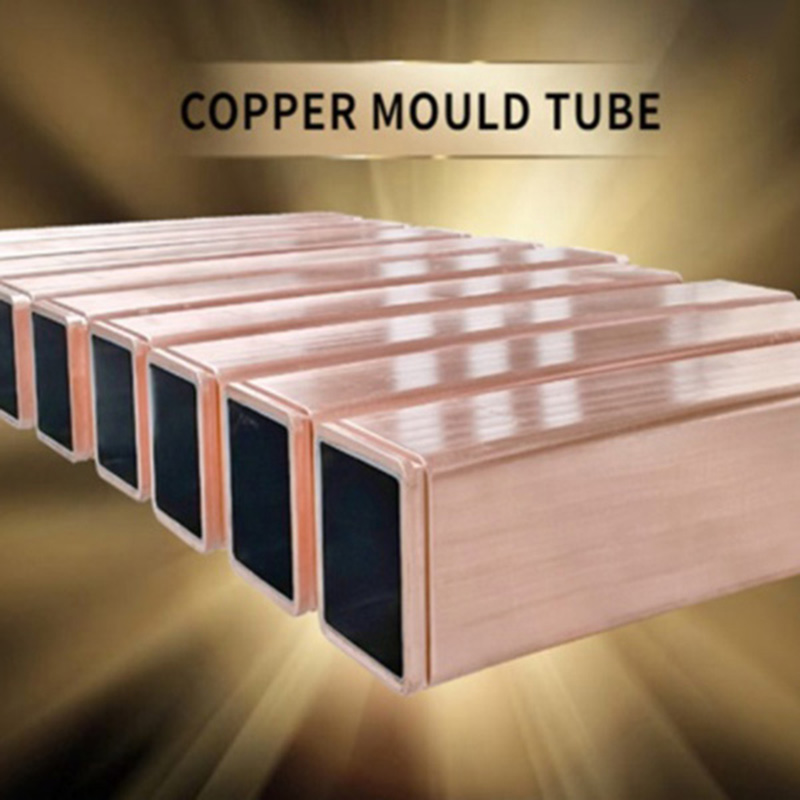

Composite Copper Mold Tube

Nhanganyaya yeComposite Plating

Inoreva kune-multi-coating layer. kureva zvinhu zvemhando mbiri zvichaputirwa pachubhu yemhangura mukutevedzana. Yekutanga layer ye nickel-cobalt alloy inofanirwa kupfekedzwa pachubhu yemhangura seyepakati, zvichibva pane iyo yechipiri layer yeChrome ichaitwa se anti-wearPlating Technics:

Composite plating ndeyeHard Chrome coating, kune mhando mbiri dzeinodaidzwa kuti niclel-cobalt alloy, imwe yacho inonzi amido-sulfonic acid system ine nickel aminosulfonate & cobalt aminosulfonate seyakagadzirwa asi imwe yacho sulfuric acid system ine nickel sulphate & nickel. cobalt sezvishandiso. Iyo yekutanga yepamusoro kune yekupedzisira mune tekinoroji yenickel sulphate ine kushushikana kwakanyanya kungangodonha kubva pakupfeka. Kusiyana neizvi, amido-sulfonic acid system ine kuderera kwekunetseka kwekugadzikana kwakanaka.

Zvakanakira

Nickel-Cobalt kupfekedza sechinhu chekuchinja kuti chiwedzere hupenyu hwekupfuura kwesimbi yemvura, nemamwe mazwi, sezvo kuwedzera kwemhangura uye chrome kwakasiyana zvachose, mukupisa nekutonhora, kuwedzera kuderera kunopa kudonha. kubva kupfeka. Naizvozvo, pamberi pe chrome coating, shanduko ye nickel-cobalt inoshanda buffer kusunungura kubva kumatambudziko ekudonha, izvo zvinoderedza zvakanyanya kukanganiswa kwejasi mukuita kupisa uye kutonhora kuwedzera hupenyu hwepasi.

Tembiricha: 20 ℃, (1E-6 / K kana 1E-6 / ℃)

| Metal | Expansion Factor |

| Mhangura | 6.20 |

| Nickel | 13.0 |

| Chrome | 17.5 |

Pfuura Hupenyu hwesimbi Metal: 8,000MT (Chrome Plating)

Pfuura Hupenyu hwesimbi Metal: 10,000MT (Composite Plating)

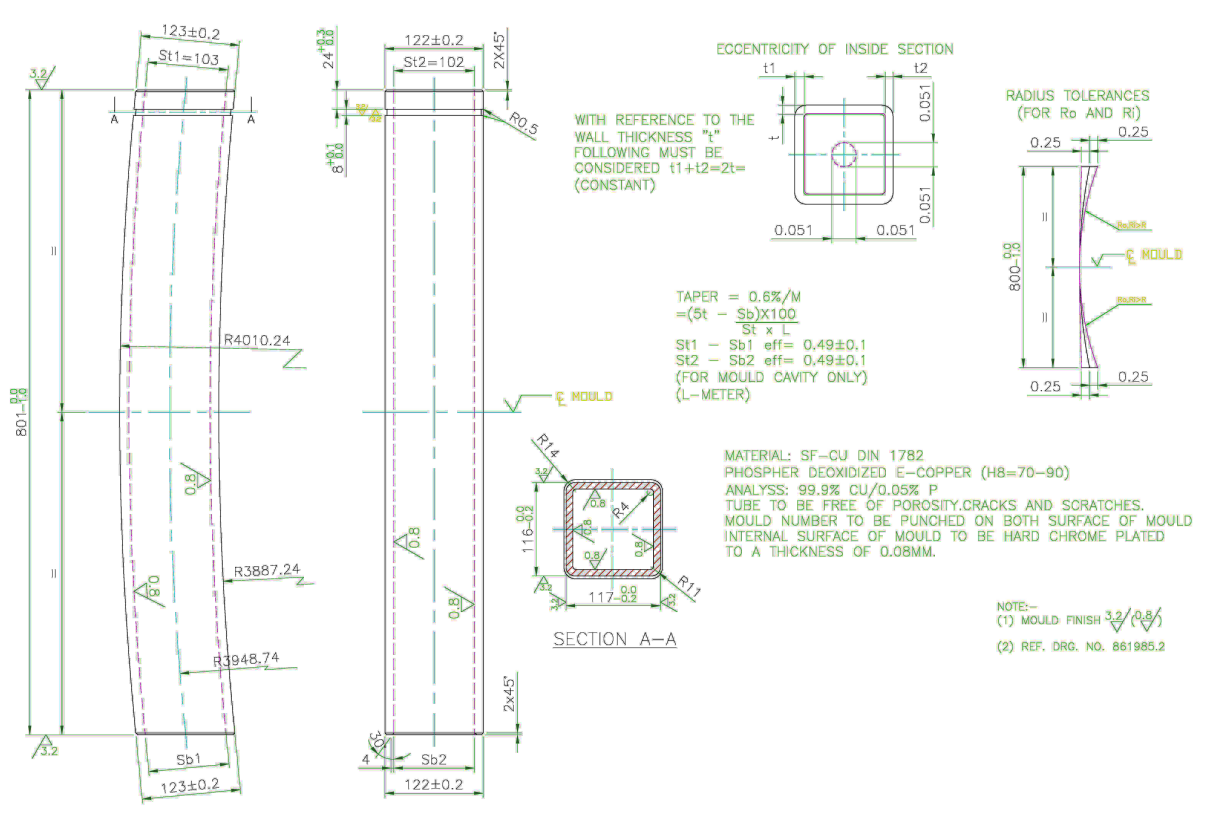

mhangura mold machubhu ekuenderera mberi achikanda muchina ane hunhu hwakanaka seanotevera:

1. Yakanakisa abrasion kuramba;

2. Kushingirira tembiricha;

3. Kuramba kwakanaka kwekuora;

4. Simba repamusoro uye kuoma kwepamusoro;

5.Kupisa kupisa kwakanaka