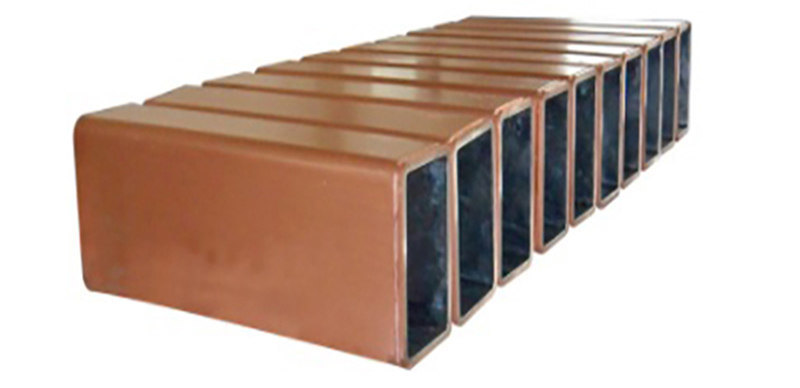

Zvishandiso zvemhangura mold tubes zvinofanirwa kunge zviri izvo zvine simba rakanaka rekusimba, kuneta simba, kuomarara kwakakodzera, kuderera kurefu uye yakanyanya kupisa conductivity coefficient. Nekuda kweizvozvo, zvinhu zvakaita se phosphorous deoxidize mhangura (DHP), CUAG, CR-ZR-CU inogamuchirwa zvakanyanya nevashandisi venyika dzese. Coatings: Mhangura ine kuomarara kwakaderera izvo zvinotungamira kune yakaderera anti-abrasive pfuma. Nokudaro, nzvimbo iri pazasi yezviumbwa, uko kushushikana kunowedzera zvakanyanya nekuda kwehombodo, kuchave kwakanyanya kupfeka. Kuti uwedzere hupenyu hwenguva yehuvhu hwemhangura, Uniform mold yemukati yekuputira nekuoma kwakakodzera kunodiwa. Mazhinji emhangura mold machubhu ediki saizi billet casting haashandiswe mune chero yekukanda sisitimu uko kune yakasimba yekukanda rukova rutsigiro, saka ivo vanonzwa zvakanyanya kuti vapfekwe. Isu tinoshandisa yakaoma chrome plating kuti tiwedzere hupenyu hwemachubhu mold. Ukobvu hweplating huchadzorwa mumhando yepamusoro. Kana kuri kupfekedzwa kwemaplate emhangura mold, zvichibva pamakore edu eruzivo, tinokwanisa kupa Cr coating, Ni-Cr coating, Ni-Fe coating kusangana nezvinodiwa nevatengi vakasiyana kumba nekune dzimwe nyika.

Nguva yekutumira: Zvita-30-2022